发布时间:2020-03-13 11:03:52 阅读:3192 次

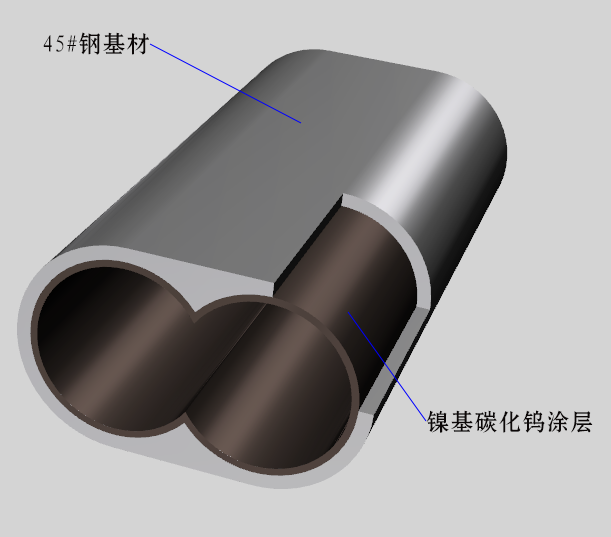

With the development of more mixed modification engineering plastics raw materials, the heart parts of extruder not only have higher wear resistance, but also more corrosion resistance.As a response, the bushing often requires the use of tungsten carbide particles to strengthen the nickel base material, and the cost will be significantly increased if the integral alloy elliptical liner is simply used.So we developed a third of the "double metal elliptical inner bushing", effective alloy layer thickness is 1.5 mm or so only can greatly satisfy) cylinder to both the requirements of the service life of the wear resistance and corrosion resistance increase, especially applied to the inner hole is more than 60 mm).

RX101A合金衬套是我公司研发的专门用于螺杆挤出内衬套的材料,这种材料因具有优异的抗磨性能和耐腐蚀性 能,超高的性价比,十年间已有超过四千台以上设备的使用。

RX101A alloy bushing is developed by our company specially for the screw extrusion lining sleeve material, this material has excellent anti-wear property and corrosion resistance, high cost performance, the use of more than ten years more than four thousand sets of equipment.

RX101B合金衬套是为了适应不同客户需求在RX101A基础上开发的新型材料,提高了合金含量,采用了真空热等 静压工艺HIP (1200°C_1400°C的真空中加以1000-2000大气压使材料达到理论完成密度),进一步提高了耐磨性能。

RX101B alloy bushing is in order to meet the different needs of customers on the basis of RX101A development of new materials, increase the content of alloy, the vacuum hot isostatic pressing process HIP (1200 °C - 1200 °C in a vacuum to atmospheric pressure to material theory, 1000-2000 complete density), further improve the wear resistance.

RXW35合金衬套是我公司历经数年研发的新工艺,衬套内表面烧结1.5mm-2mm厚镍基碳化钨合金,结合层冶金状 态结合,耐腐性优于316L不锈钢,耐磨性是6542高速钢的6倍。

RXW35 alloy bushing is my company after several years of research and development of new technology, bushing sintering on the inner surface of 1.5 mm - 2 mm thick nickel-based tungsten carbide alloy, metallurgical combination layer state combination, corrosion resistance is better than that of 316 I stainless steel, wear resistance is 6542 high speed steel 6 times.

上一篇:膨化机抗磨损合金衬套

下一篇:没有了